About US

Panatack, Enterprises Co.,Ltd

Your Trusted Contract Manufacturing Partner.

Panatack Enterprises Co., Ltd. was founded in 2002 and has been committed to the field of manual nail guns and pneumatic nail guns for more than 20 years.

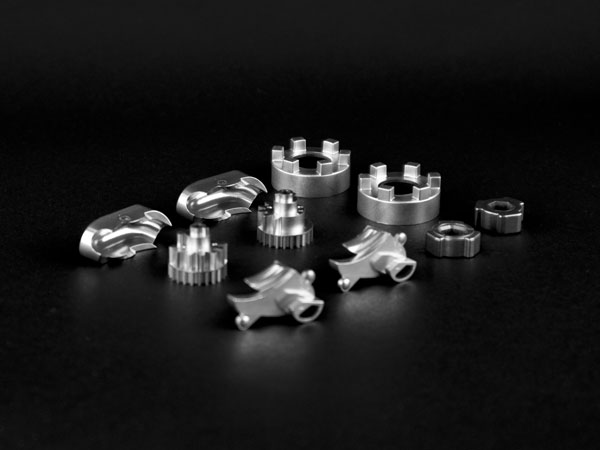

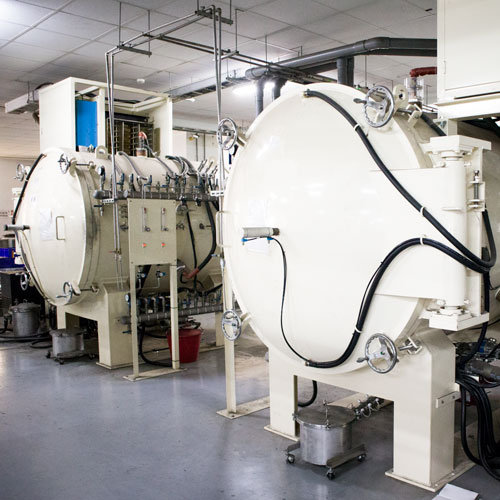

In 2005, Metal Injection Molding (MIM) was introduced to produce complex and precise metal structure parts.

In the field of metal injection molding (MIM) technology, Panatack Enterprises Co., Ltd. has always insisted on the notion that only continuous improvements will be able to flourish in this competitive environment. Providing high-quality products, prompt delivery, reasonable prices and customer satisfaction is the company's top priority.

Professional

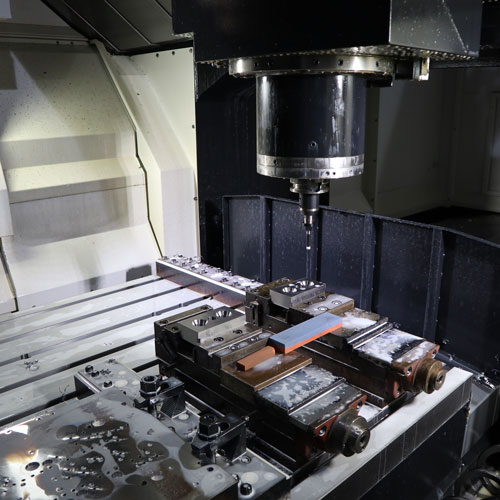

Panatack has over 30 years of experience in the development of moulds and tooling.

Technology

Design ➜ Tooling ➜ Prototyping ➜ Inspection

➜ Mass Production.

Service

For subsequent mould maintenance and repair?

We provide unlimited service